Views: 0 Author: Site Editor Publish Time: 2021-04-13 Origin: Site

Over the years, graphite parts have played an important role in the whole aluminum extrusion process. However, the birth of industrial felts has caused a great impact on its status. In fact, many people may not even know much about this new material. Well, this article will give you an overall comparison based on some key factors during extrusion.

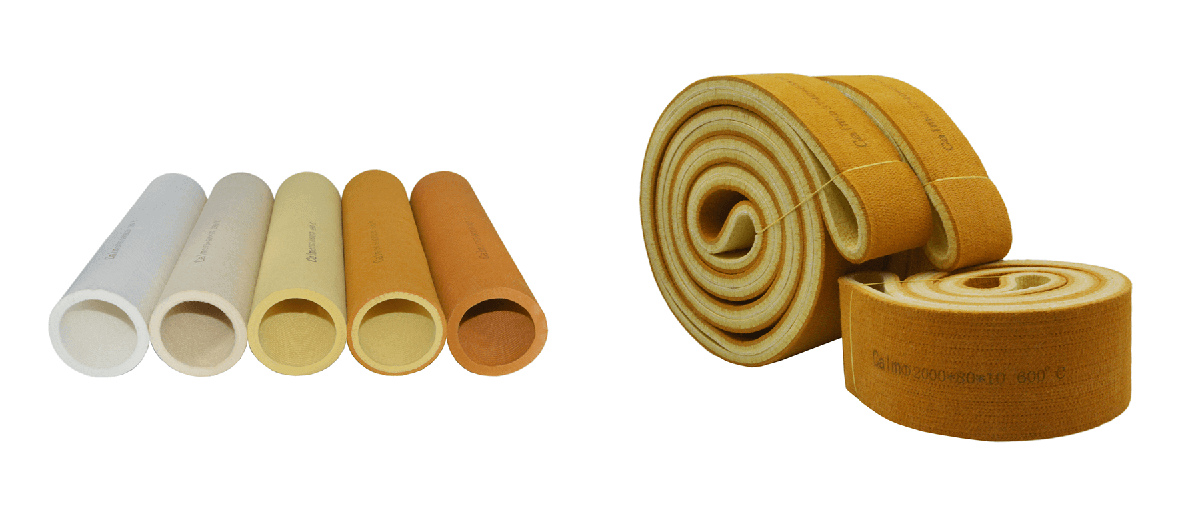

Industrial felt - According to different raw materials, it can be divided into 4 types - PBO, Kevlar, Nomex, and Polyester. These four new-tech fibers will go through carding, combing, needling, and a series of processes to form industrial felt. Different felt products are available in various extrusion stages, including the felt roller cover, felt belt, felt strip, and more.

Graphite - The higher the density of graphite, the higher the hardness. In general, high-purity graphite refers to graphite with a carbon content of 99.9% or more. It is easy to machine and can be processed in various shapes according to requirements. In general, graphite parts for extrusion press include 3 types - graphite plates, rolls, and strips.

After making clear what they are. Let's find out which is better from the following two aspects, which are hugely related to the extrusion process.

The melting point of graphite is 3850±50 ℃, and the boiling point is 4250 ℃. The strength of graphite will enhance as the temperature increases and doubles at 2000℃. In addition, graphite can withstand drastic temperature changes without any damage or cracks, although it may have slight changes in volume.

The heat resistance of industrial felts, on the other hand, varies from fiber to fiber.

PBO (600℃) - ultra-high temp. zone

Kevlar (480℃) - high temp. zone

Nomex (280℃) - middle temp. zone

Polyester (180℃) - low temp. zone

From the above data, we can see that although its temperature resistance is much lower than that of graphite, it is sufficient for aluminum extrusion (working temp: about 500℃). Moreover, in terms of price, it is cost-effective to choose based on the operating temp or temp zone. In a word, it is tailor-made for aluminum extrusion and helps to reduce production costs.

Compared with graphite, the industrial felt has the better protective ability for the extruded profiles. As you know, the color of graphite usually iron-black or steel-gray. This makes it easy to leave black marks on the profile surface. What's more, graphite has a Mohs scale hardness of 1-3, but the profile just out of the extruder is hot and soft. It is very common for graphite to cause damage to the profile surface. As a result, this requires a lot of time and labor spent on checking and cleaning profiles.

Later, as a good alternative to graphite, industrial felt has become the popular option for many profile manufacturers. With the needle-punched technique, the felt features a soft touch and smooth surface without burr. It can prevent swarf and dirt from adhering to the profile and ensure the clean and smooth surface of the profiles. By the way, resin-treated industrial felt is more durable and has better wear resistance.

If you want to know more about industrial felt, please click here or feel free to contact us at toby@gdcalm.com. Calm is the top industrial felt product in China, with more than 18 years of experience. We have been supplying high-quality industrial felt products for aluminum extrusion factories all over the world.